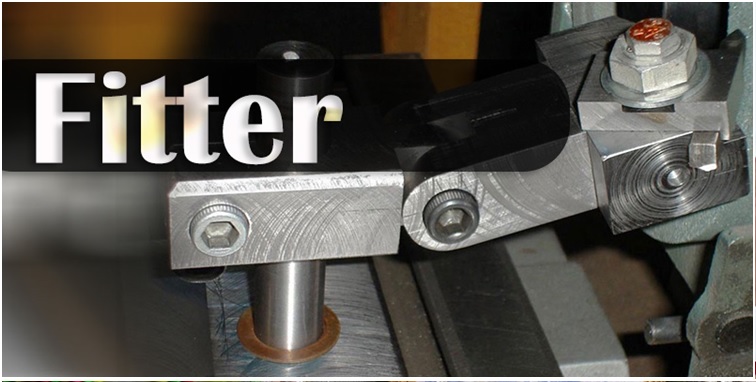

Fitter

Course Details

Trades Duration: 2 Year

Number of Seats:20

Minimum Qualification Eligibility: 10th Passed

Trade Type: Engineering

During the two-year duration a candidate is trained on subjects Professional Skill, Professional Knowledge, Engineering Drawing, Workshop Science & Calculation and Employability Skill related to job role. In addition to this a candidate is entrusted to make/do project work and Extra Curricular Activities to build up confidence. The practical skills are imparted in simple to complex manner & simultaneously theory subject is taught in the same fashion to apply cognitive knowledge while executing task. The practical part starts with basic fitting with tolerance level ± 0.5mm and finally to ± 0.02mm and angular tolerance from 1 to 10′ at the end of the course. The broad components covered under Professional Skill subject are as below:

Brief description of job roles:

- Electronics Fitter, General fits, assembles and repairs various kinds of electronic equipment in factory or workshop or at place of use. Examines drawings and wiring diagrams; checks parts for accuracy of fit and minor adjustments; assembles parts or mounts them on chassis or panels with aid of hand tools; installs and connects wiring, soldering joints equipment, diagnoses faults with aid of electronic testing equipment; dismantles equipment if required and replaces faulty parts or wiring.

- Electronics Fitter, other include all other workers engaged in fitting, assembling, repairing and maintaining electronic equipment, machinery, appliances, etc., not elsewhere classified.

- Electronics Mechanic; Electronic Equipment Mechanic repairs electronic equipment, such as computers, industrial controls, transmitters, and telemetering control systems following blueprints and manufacturer's specifications and using hand tools and test instruments. Tests faulty equipment and applies knowledge of functional operation of electronic units and systems to diagnose cause of malfunction. Tests electronic components and circuits to locate defects, using instruments, such as oscilloscopes, signal generators, ammeters and voltmeters. Replaces defective components and wiring and adjusts mechanical parts, using hand tools and soldering iron. Aligns, adjusts and calibrates testing instruments. Maintains records of repairs, calibrations and test.

- FIRST YEAR: The practical part starts with basic fitting in the beginning and the candidate also imparted training on allied trades viz., Sheet Metal, Welding (Gas & Arc) which leads to multiskilling. In the basic fitting the skills imparted are sawing, filing, marking, chipping, measurement, riveting, soldering, brazing, drilling and observation of all safety aspects is mandatory. The accuracy achieved is of±0.25 mm. The safety aspects cover components like OSH&E, PPE, Fire extinguisher, First Aid and in addition 5S being taught. Different drilling operations (through, blind, angular), reaming, offhand grinding, tapping, dieing, different fits viz., sliding fit, etc., scraping, fastening (nuts & bolts, riveting, studs, screws, etc.,). The accuracy achieved is of± 0.04 mm and angular accuracy to 30minutes. Different turning operations on lathe (step, grooving, chamfering, drilling, boring, knurling & threading), simple repair, overhauling and lubrication work on machine are being taught in the practical. SECOND YEAR: Power tool operation, different complex assembling and fitting, fastening, lapping, making gauges, pipe works and pipe joints, Dismantling, overhauling& assembling valves are covered. The accuracy achieved is of an accuracy of ± 0.02 mm & 10 minutes. Making & using drill jigs, making of critical components, repair & maintenance of power transmission system, making of template &complex gauges, identify different Pneumatic & hydraulic components and circuit construction, repair & maintenance of machinery like lathe, drill, grinding, bench drilling, Inspection of Machine tools, Accuracy testing of Machine tools and erection of simple machines are being performed as part of practical training. Professional Knowledge subject is simultaneously taught in the same fashion to apply cognitive knowledge while executing task. In addition components like Physical properties of engineering materials, Interchangeability, Method of expressing tolerance as per BIS Fits.